Understanding the Process of Welding Inspection Racine for Ideal Outcomes

Understanding the Process of Welding Inspection Racine for Ideal Outcomes

Blog Article

Equipping Your Service With Customized Welding Evaluation Services for every single Job

In the realm of service procedures, the significance of welding inspections tailored to particular job requirements can not be overstated. Customized evaluation intends not only work as an important element of quality assurance yet likewise play a critical duty in guaranteeing the structural integrity and safety and security of completion item. By diving right into the nuanced aspects of welding assessment services, organizations can unlock a realm of advantages that extend beyond simple compliance. Whether it be small-scale tasks that require precision or large endeavors needing streamlined performance, the tailored approach to welding evaluations stands as a foundation for success.

Importance of Tailored Welding Inspections

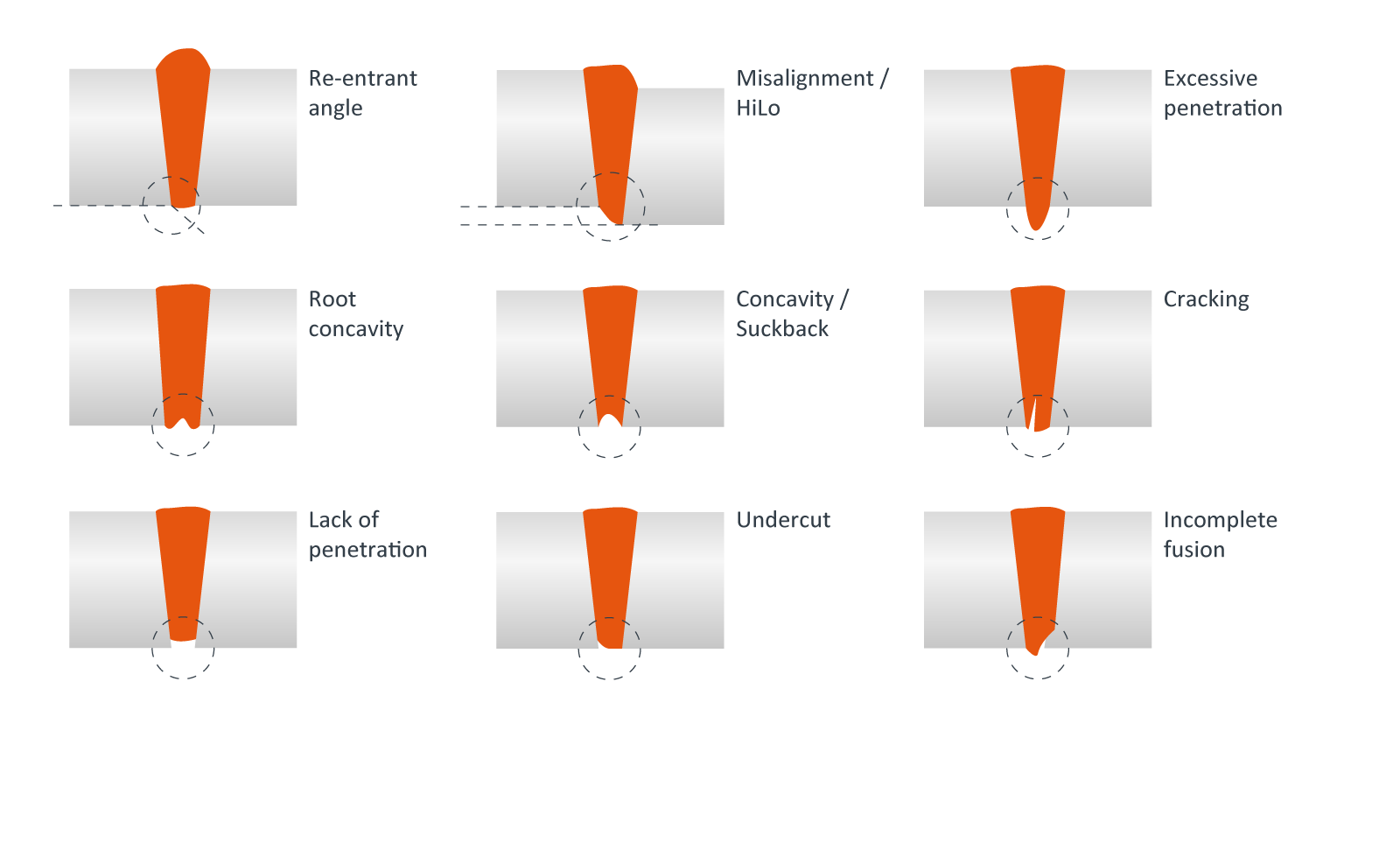

Customized welding evaluations play a vital duty in making certain the high quality and stability of welds in various industries. These specialized assessments are customized to fulfill the certain demands of each project, thinking about factors such as the sort of products being welded, the welding strategy made use of, and the sector requirements that require to be abided by. By customizing the evaluation procedure, possible problems and issues can be recognized and resolved early on, protecting against costly rework or failures down the line.

Different markets have differing requirements when it comes to welding quality, and customized evaluations help services satisfy these requirements effectively. In addition, tailored examinations help boost total efficiency and performance by enhancing the evaluation procedure to concentrate on the most important areas.

Advantages of Personalized Examination Strategies

Custom-made evaluation plans supply businesses a strategic benefit by exactly straightening examination procedures with the special requirements of each welding task. By tailoring inspection plans to match the details demands of a project, businesses can make sure that all vital facets are thoroughly taken a look at, thus minimizing the risk of welding flaws and making certain conformity with market requirements. One of the primary advantages of personalized evaluation plans is the enhanced effectiveness they give the welding process. By focusing on the most vital locations of a job, examiners can allocate their time and sources better, bring about faster task completion and lowered downtime.

Custom-made evaluation plans supply businesses a strategic benefit by exactly straightening examination procedures with the special requirements of each welding task. By tailoring inspection plans to match the details demands of a project, businesses can make sure that all vital facets are thoroughly taken a look at, thus minimizing the risk of welding flaws and making certain conformity with market requirements. One of the primary advantages of personalized evaluation plans is the enhanced effectiveness they give the welding process. By focusing on the most vital locations of a job, examiners can allocate their time and sources better, bring about faster task completion and lowered downtime. Additionally, customized assessment strategies assist companies conserve prices in the future by protecting against rework and lessening the possibility of job delays. By capturing prospective problems early on through tailored examinations, businesses can resolve them quickly, staying clear of expensive blunders down the line. Additionally, tailored evaluation strategies can boost overall task quality by giving an extra detailed and extensive assessment of welding procedures, products, and handiwork. This, consequently, can cause improved customer complete satisfaction and a stronger online reputation for supplying top notch welding tasks.

Tailored Solutions for Small-Scale Projects

For small-scale welding tasks, specialized inspection services can be customized to meet the specific requirements and restrictions of the job range - Welding Inspection Racine. While larger projects commonly have a lot more standardized assessment processes, small projects require a much more concentrated and tailored strategy because of their unique attributes

In small jobs, every weld is critical, and even minor defects can have substantial effects. Customized welding evaluation solutions for these projects involve a comprehensive understanding of the project objectives, materials used, welding methods, and market guidelines. By personalizing the assessment plan to fit the range and complexity of the project, prospective problems can be recognized early, resulting in improved weld high quality and overall job success.

Furthermore, tailored solutions for small projects can help maximize sources and lessen costs. By focusing evaluation initiatives on areas that matter most for the details project, unnecessary assessments can be stayed clear of, saving both time and cash. This targeted strategy makes sure that the evaluation process is efficient, reliable, and ultimately adds to the successful conclusion of small welding projects.

Furthermore, tailored solutions for small projects can help maximize sources and lessen costs. By focusing evaluation initiatives on areas that matter most for the details project, unnecessary assessments can be stayed clear of, saving both time and cash. This targeted strategy makes sure that the evaluation process is efficient, reliable, and ultimately adds to the successful conclusion of small welding projects.Enhancing Effectiveness in Big Tasks

In the realm of large-scale welding jobs, the focus shifts in the direction of enhancing evaluation processes to enhance overall effectiveness and project success. In such substantial ventures, time is of the essence, making effectiveness a vital factor in conference target dates and ensuring top quality. Using innovative evaluation strategies, such as automated welding inspection systems and real-time monitoring tools, can considerably decrease evaluation times while enhancing accuracy. By incorporating these innovations into the job process, assessors can rapidly identify variances, problems, or locations requiring rework, permitting prompt corrective activities.

Moreover, developing clear interaction networks and procedures between inspection teams, task managers, and welders is important for ensuring that examinations are carried out promptly which any problems are promptly dealt with. Carrying out an organized method to evaluation organizing, focusing on crucial welds, and allocating resources properly can help avoid traffic jams and maintain the task on course. Constant training and upskilling of examination personnel likewise play a crucial role in boosting performance in large tasks, making certain that inspectors are furnished with the latest understanding and techniques to do their obligations successfully.

Ensuring Conformity and Company Defense

Keeping stringent adherence to welding policies and industry standards is critical for protecting organization passions and making certain functional compliance. By prioritizing conformity, services can alleviate dangers, avoid expensive penalties, and support their track record within the industry. Welding assessment services play a crucial function in guaranteeing that all welding refines meet the needed requirements and codes, providing businesses with the assurance that their jobs are carried out in a safe and compliant fashion.

Furthermore, compliance with welding regulations is not practically meeting legal needs; it is additionally concerning making sure the security of personnel, the public, and the environment. Non-compliance can lead to accidents, architectural failures, and environmental threats, all of which can have severe effects for a business's lower line and credibility. By buying tailored welding evaluation solutions, services can proactively determine and deal with compliance problems prior to they intensify, thus safeguarding their rate of interests and fostering a culture of safety and top quality within the company.

Verdict

Finally, customized welding inspection solutions play an important function in equipping organizations by making certain quality, compliance, and performance in jobs of all dimensions. Customized assessment plans aid organizations fulfill market criteria, shield their reputation, and review minimize risks. Whether it's a large endeavor or a small-scale project, customized services can improve high site link quality control and overall success. Spending in tailored welding evaluations is a calculated decision for businesses seeking to attain excellence in their welding processes.

In addition, tailored evaluations assist enhance overall efficiency and productivity by streamlining the evaluation process to concentrate on the most crucial areas.Custom-made inspection strategies offer services a tactical advantage by precisely lining up inspection procedures with the special demands of each welding job. By concentrating inspection efforts on areas that matter most for the details task, unneeded assessments can be avoided, conserving both time and money. Employing innovative inspection methods, such as automated welding examination systems and real-time surveillance devices, can substantially lower examination times find more info while boosting precision.Moreover, establishing clear communication networks and procedures in between inspection groups, project managers, and welders is essential for making sure that assessments are carried out immediately and that any type of issues are promptly addressed.

Report this page